In our lives, there are various kinds of display screens, and their application environments are also different. Among them, COG LCD display is a very common type. Generally, COG display screen can be used in industrial applications. Displays, automotive displays and portable devices. So, for manufacturers, what are the main concerns when choosing a high-quality COG? This article will share it with you in detail!

The characteristic of COG packaging technology is that the driver IC is directly packaged on the liquid crystal glass through anisotropic conductive glue (ACF), and the conductive bumps of the driver IC are interconnected and packaged with the ITO transparent conductive pad on the liquid crystal glass. In this process , we mainly focus on these aspects:

LCD (Liquid Crystal Display), which is the abbreviation of liquid crystal display. For more knowledge about LCD screens, please click on the link: How does an LCD screen work? , AFC, silicone, IC, FPC. As a display manufacturing expert with more than 20 years of experience, Hongtai Technology has made a summary from many aspects by comparing other COG products on the market and is committed to helping customers choose the highest quality products.

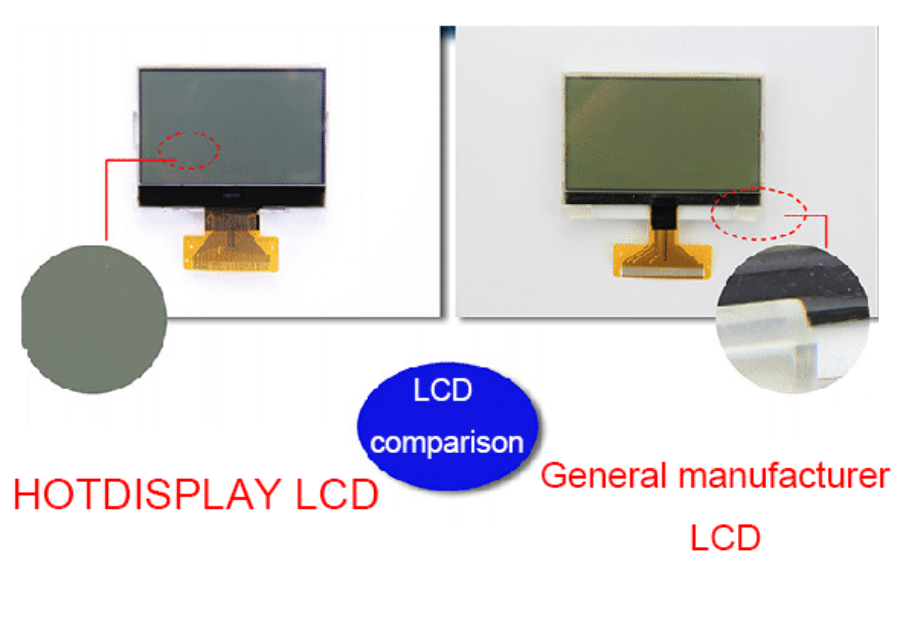

Comparison between Hot Display’s LCD and LCDs from general merchants(As shown in Figure 1)

(Figure 1)

HOT Display LCD:

Using domestic first-tier manufacturers, LCD production technology and environment are excellent, and quality control is strict. Reliability is the first priority in the design, and the LCD width is not reduced to save costs.

General Supplier LCD:

Using LCDs from general manufacturers, their production technology and environment are poor, and quality control is not strict. LCD circuits are prone to electrical corrosion. In order to save costs, the design adds a backlight inner frame and reduces the LCD density. Reduced FPC reliability.

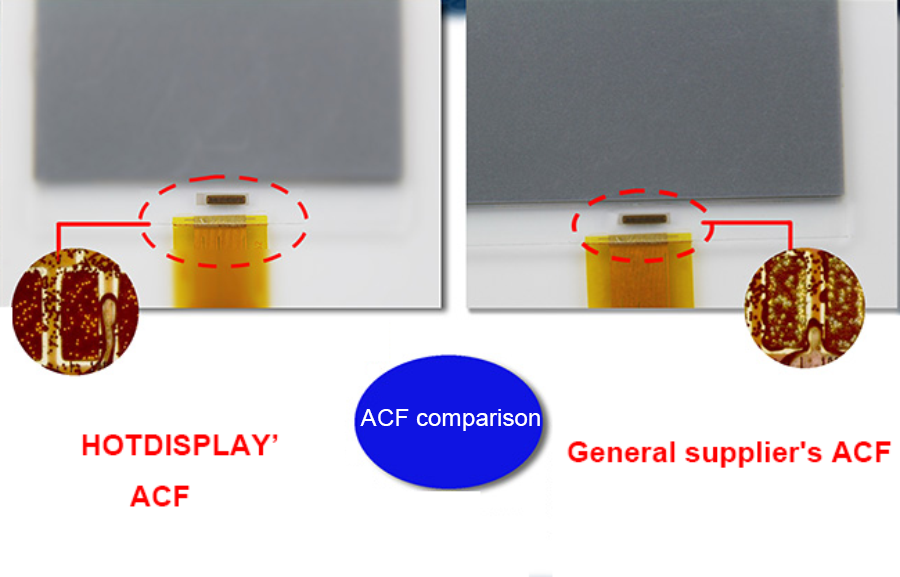

Comparison between Hot Display’s AFC and AFC from general merchants(As shown in Figure 2)

(Figure 2)

HOT Display AFC:

The conductive gold particles are in good contact with ITO. The anti-oxidation performance of pure gold is good and the conductivity will not decrease with the increase of use time. It adopts the international first-line Sony and HITACHI brand ACF. Both the tensile strength of ACF and its anisotropic conductive performance are in The industry is second to none. ACF is the connecting bridge between IC, FPC and LCD. The quality of ACF directly affects the display function of the display screen.

Reliability, the ACF price of first-tier brands is more than five times higher than other brands, Xinhongtaishi

We always put product quality first and never give up on quality for the sake of price competition.

General Supplier AFC:

When using ordinary brand ACF, the gold component in the conductive particles is insufficient. In order to reduce costs, other cheap alternative materials are used. Its anti-oxidation performance and tensile strength performance will decrease with the increase of use time, and displays such as disconnection and black screen will occur. bad.

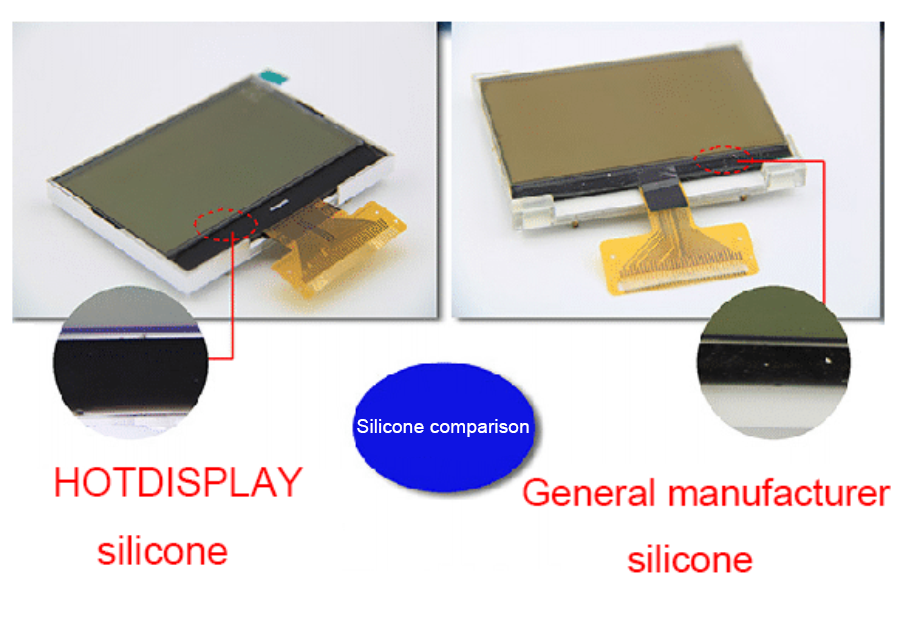

Comparison between Hot Display’s silicome and silicomes from general merchants(As shown in Figure 3)

(Figure 3)

HOT Display Silicome:

Use silica gel produced by first-line manufacturers such as Toshiba.Good reliability.

General Supplier Silicome:

Generally manufacturers use silicone .Use silica gel produced by ordinary domestic manufacturers.Reliability is poor.

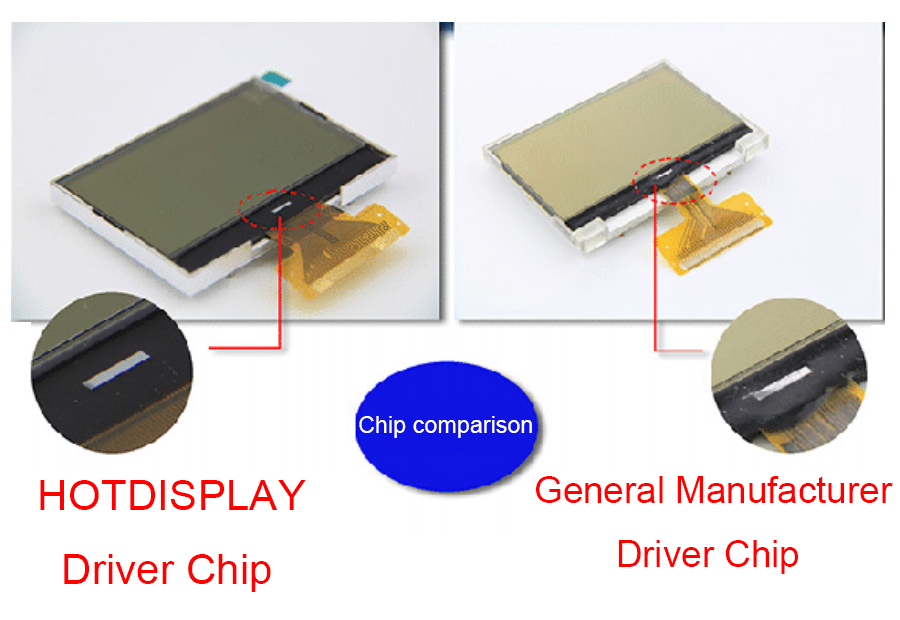

Comparison between Hot Display’s IC and IC from general merchants(As shown in Figure 4)

(Figure 4)

HOT Display IC:

Using original imported IC, it has strong driving ability and strong anti-interference ability.

General Supplier IC:

Using other cheap ICs has poor driving ability and poor anti-interference ability.

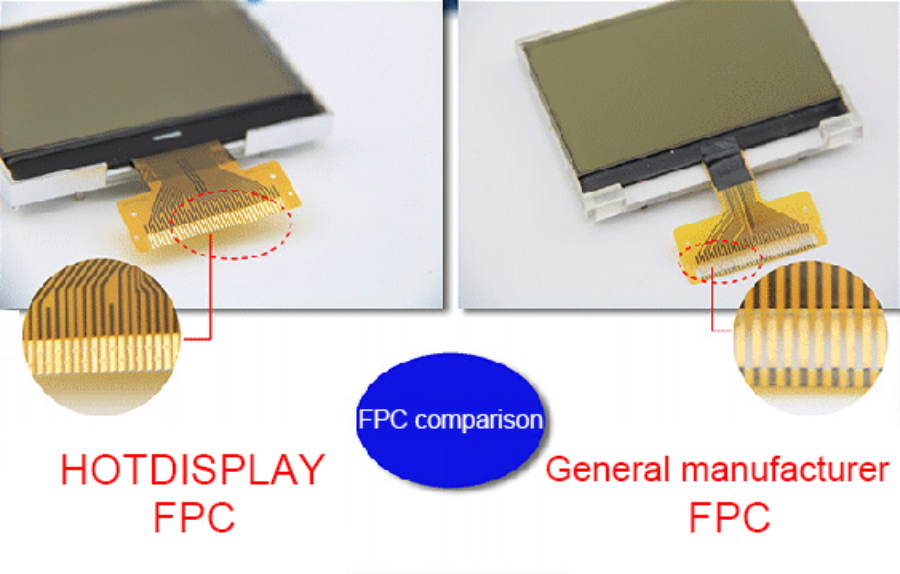

Comparison between Hot Display’s FPC and FPC from general merchants(As shown in Figure 5)

(Figure 5)

HOT Display FPC:

Sign technical specifications with each FPC supplier to stipulate the relevant technical specifications, materials, processes, etc. of FPC. The copper foil material is all rolled copper, with good welding and ductility properties.

General Supplier FPC:

There are no clear requirements for the relevant technical specifications, materials, processes, etc. of FPC. In order to reduce procurement costs, the copper foil will be replaced by electrolytic copper. The welding position is easy to break and has poor ductility.

For information about COG display screens, please contact us!

Search

Search