What is FPC and how it works

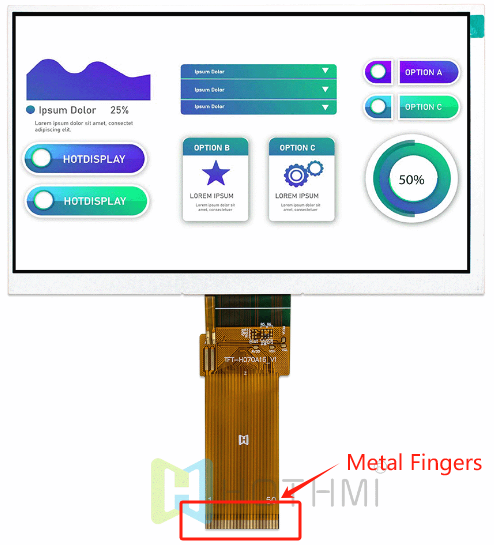

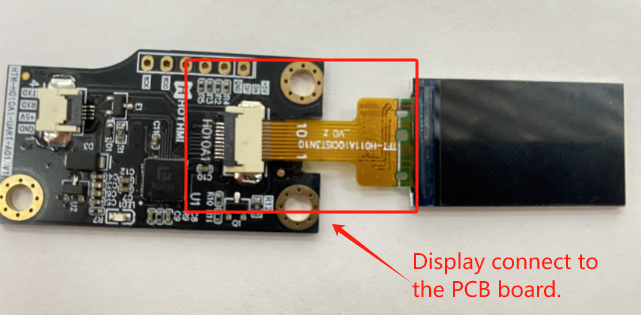

The working principle of the FPC connector is quite straightforward, but also very interesting. FPC-Flexible Printed Circuit is a printed circuit with high reliability and excellent flexibility made of polyester film or polyimide as the substrate. By embedding the circuit design on the bendable thin plastic sheet, a large number of precision components can be stacked in a narrow and limited space to form a bendable flexible circuit. Thin metal wires are printed on the flexible plastic strips, so they are designed to transmit electrical signals between different parts of the device. Each metal wire is an independent path for the electrical signal, and each signal carries different types of information. All signal lines are finally gathered into a row of neat metal strips, which we call "metal fingers". These metal fingers are generally made of copper materials, which are resistant to friction, conductive, and have high hardness, so the transmission signal has good stability. When the FPC connector is connected to the device, it builds a bridge between different parts, forming a stable electrical connection. Then, when the device is turned on, the electrical signal will flow along these metal wires, so that the various parts of the device can communicate with each other.

Advantages of FPC

1. Flexibility

Flexibility is the biggest advantage of using flexible printed circuit boards, which can be bent, folded, and rolled freely, and are easy to connect; they can be moved, stretched, and arranged at will. It is easy to reduce the size of electronic products. Because the FPC board is elastic, it can be easily placed around the edges and boards. Flexibility also requires little or no wiring in the connection, which eliminates faults in the wiring connection and improves the reliability of the equipment.

2. FPC connector is light and saves a lot of space

Compared with PIN cables, displays with FPC are more than 60% lighter. This makes storage and installation easier and more convenient. They can be bent, twisted and folded, which is a very beneficial feature in complex and tightly fitting assemblies.

3. FPC connectors can withstand more bending cycles

The standard materials used in FPC cables can withstand up to 200 bending cycles.

4. Anti-vibration performance of FPC connector

Because the FPC board is flexible and lightweight, it can absorb vibration and effectively reduce its impact on the connection.

5. FPC connectors can withstand harsh environments

FPC connectors can be made of corrosion-resistant, moisture-proof, waterproof and shock-proof materials, making them suitable for use in harsh operating environments.

6. FPC connectors can be used for high-power applications

FPC connector boards are loaded with thick copper layers for high-power applications. Flexible boards are suitable for surface mount technology. (SMT) Since FPC boards are able to provide strain-free bonding sites for SMT components, they are ideal for use in SMT applications. The flexible base absorbs thermal stress, reducing the chance of solder joint failure.

7. FPC connector can bend dynamically

FPC boards can flex more than flat ribbon cables. Therefore, they are the preferred connector type to provide reliable interconnects for applications that require millions of flexes, such as interconnections between moving parts.

8. Reliability of FPC connector

The routing on the FPC board is determined by the artwork, eliminating the possibility of wiring errors. This translates into highly reliable interconnects.

9. FPC connectors are cost-effective

With FPC, the finished component packaging size is smaller and the material cost is lower. In addition, wiring errors are reduced, which shortens the test time and reduces additional costs. Thirdly, compared with metal PIN headers, FPC does not require welding, thus reducing labor costs and the cost of scrapped products due to poor welding technology.

10. Easy to install.Thanks to its simple and refined structural design, the installation and disassembly of FPC connectors are very convenient. It is widely praised in the industry. In summary, FPC connectors are light and thin, highly integrated, have high-quality electrical performance, long plug-in life, solid and reliable structure, and are easy to install.

FPC connector products have the following pitches and conventions:

1. The cable spacing of FPC connectors are: 0.3mm, 0.5mm, 0.8mm, 1.0mm, 1.25mm, 2.0mm, 2.54mm;

2. The cable length of FPC connectors: 15mm~ANY;

For more information about FPC, please contact us directly.

Search

Search